PUBLIC WEBCAST AUCTION | WEDNESDAY, NOVEMBER 14

WEDNESDAY, NOVEMBER 14 AT 10:00 AM PST

PRISTINE ASSETS OF A MANUFACTURER OF SUPER ALLOY & TITANIUM FABRICATIONS FOR IGT & AEROSPACE INDUSTRIES

SURPLUS TO THE ONGOING OPERATIONS OF INTEGRATED ENERGY TECHNOLOGIES, INC., A DELAWARE CORPORATION, A SUBSIDIARY OF DONCASTERS US HOLDINGS 2018, INC.

INSPECTION: TUESDAY, NOVEMBER 13 FROM 8:00 AM TO 4:00 PM PST OR BY SPECIAL APPOINTMENT. ALL PARTIES WISHING TO INSPECT MUST PRE-REGISTER WITH PERFECTION INDUSTRIAL SALES.

LOCATION: DONCASTERS MEXICO, PARQUE INDUSTRIAL FINSA, TIJUANA, MEXICO

2017 PRIMA POWER 795XL & 430BD 5-AXIS FIBER LASER SYSTEMS, (2) MORI SEIKI MH-633 HORIZONTAL 4-AXIS MACHINING CENTERS, 2016 HAAS VF-6 VERTICAL MACHINING CENTER, MORI-SEIKI SL600 CNC LATHE, MORI-SEIKI CL-203 CNC LATHE, OKUMA LB25II CNC LATHE, PLATE ROLLS, PIRANHA 10’ X 1/4” SHEAR, PLANISHERS, LONGITUDINAL & CIRCULAR SEAM WELDERS, LINCOLN & MILLER WELDING POWER SOURCES, ROBOTIC WELDING SYSTEMS, FUME & DUST COLLECTORS, HYDRAULIC CAKE EXPANDERS, MATERIAL HANDLING EQUIPT. INCLUDING GORBEL CRANE SYSTEMS, CMM’S & 2018 FARO ARM INSPECTION SYSTEM, X-RAY INSPECTION & CALIBRATION SYSTEMS & MORE

5-AXIS FIBER LASERS

2017 PRIMA POWER LASERDYNE 795 XL 5-AXIS FIBER LASER, S/N 795.175, PRIMA POWER SYSTEM 94P LASER PROCESS CONTROL, 78″ X, 39″ Y, 39″ Z, BEAM DIRECTOR-900 DEGREE CONTINUOUS MOTION IN C AXIS, 300 DEGREE CONTINUOUS MOTION IN D AXIS, 90 RPM, 65 FT/MIN, IPG PHOTONICS YTTERBIUM YLS-2000/20000 LASER SYSTEM, W/ DONALDSON TORIT POWERCORE TG6 COLLECTION SYSTEM, IPG PHOTONICS LC71 CHILLER, W/ 2017 RUSACH 2-04D450 4TH-AXIS ROTARY TABLE 36″ X 84″ MACHINE BASE TABLE

2016 PRIMA POWER LASERDYNE 430 5-AXIS FIBER LASER, S/N 430.220, PRIMA POWER SYSTEM 94P LASER PROCESS CONTROL, 23″ X, 16″ Y, 20″ Z, BEAM DIRECTOR-900 DEGREE CONTINUOUS MOTION IN C AXIS, 300 DEGREE CONTINUOUS MOTION IN D AXIS, 90 RPM, 49 FT/MIN, 550 LB TABLE CAPACITY, IPG PHOTONICS YTTERBIUM YLS-1200/12000 LASER SYSTEM, W/ DONALDSON TORIT POWERCORE TG 2 COLLECTION SYSTEM, IPG PHOTONICS LC71 CHILLER

LASER

2000 GSI LUMONICS LASERDYNE 790 LASER, S/N 009, W/ AEC LASER TEMP SERIES II PORTABLE CHILLER, SYSTEM 94W LASER PROCESS CONTROL

CNC VERTICAL MACHINING CENTERS

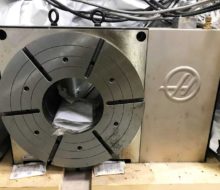

2016 HAAS VF-6/40 CNC VERTICAL MACHINING CENTER, S/N 1132913, HAAS CNC CONTROL, 64″X, 32″Y, 30″Z, 28″ X 64″ TABLE, 4,000 LB TABLE CAPACITY, 30 HP, 8100 RPM, 600 IN/MIN RAPIDS, 24 ATC, CAT 40 SPINDLE TAPER, HAAS HRT450/P3 4TH AXIS ROTARY TABLE, S/N 451146 (NEW IN BOX)

LEBLOND MAKINO FNC128-A30 CNC VERTICAL MACHINING CENTER, S/NA95-881, MAKINO PROFESSIONAL 3 CNC CONTROL, 32″ X 71″ TABLE, 49.21″X, 31.5″ Y, 27.56″ Z, 6,600 LB TABLE CAPACITY, 3500 RPM, 30 ATC, CAT 50 SPINDLE TAPER, TSUDAKOMA RNCM-401R 4TH AXIS ROTARY TABLE, S/N 910937

TREE VMC1260 EZ/32 CNC VERTICAL MACHINING CENTER, S/N 9-14-93-2071, SIEMENS ACRAMATIC 2100 CNC CONTROL, 21″ X 57″ TABLE, 32-ATC, CAT 50 SPINDLE TAPER

(2) 2001 MORI-SEIKI MH-633 CNC HORIZONTAL MACHINING CENTERS, S/N MH630AE1008 & NA, MORI SEIKI MSG-502 CNC CONTROL, CHIP BLASTER HIGH-PRESSURE COOLANT SYSTEM

CINCINNATI 20H CINTIMATIC HORIZONTAL MACHINING CENTER, S/N 55403H15Z-0007-RL91, CINCINNATI ACRAMATIC 850 CNC CONTROL 30.5″ X 101″ TABLE, 7.5 HP HYDRAULIC UNIT

CINCINNATI H-5 MAGNUM-800 CNC HORIZONTAL MACHINING CENTER, S/N ZD00A02990002, CINCINNATI A2100 CNC CONTROL, (6) 31.5″ X 31.5″ PALLETS, PALLET CHANGER, CAT 50 SPINDLE TAPER, 60 ATC

CNC LATHES

1999 MORI SEIKI SL600CMC/2000 CNC LATHE, S/N 34, MORI SEIKI MSC-501 CNC CONTROL, 31″ 3-JAW CHUCK, 10-POSITION TURRET

OKUMA LB25II CNC LATHE, S/N 1012.0704, OKUMA OSP7000L CNC CONTROL, 16.54″ SWING, 26.57″ DISTANCE BETWEEN CENTERS, 25.59″ MAX MACHINING LENGTH, 11.81″ X, 26.61″ Z, 3500 RPM

2001 MORI SEIKI CL-203 CNC LATHE, S/N 1868, MORI SEIKI MSG-803 CNC CONTROL, 10-POSITION TURRET, 8″ 3-JAW CHUCK, 2.55″ BAR CAPACITY, 16″ SWING, 3500 RPM, TURBO CHIP CONVEYOR, MICRO AIR OM550 CLEAN AIR SYSTEM

OKUMA & HOWA ACT 35 CNC LATHE, S/N 00120, FANUC 18-T CNC CONTROL, 12-POSITION TURRET, 12″ 3-JAW CHUCK, 20″ SWING, 24″ MACHINING LENGTH, 3500 RPM

HYDRAULIC PRESS BRAKE

PACIFIC J135-10 HYDRAULIC PRESS BRAKE, S/N 9299, 135 TON X 10’ CAPACITY, 104″ BETWEEN HOUSINGS, AUTOMAC AUTOGAUGE CNC100 CONTROL, AUTOGAUGE G24 BACKGAUGE

BENDING ROLLS

BUILT-RITE NEW DIMENSION P6.250 3-ROLL POWER BENDING ROLL, S/N 04991701

NIAGARA 5-36 3-ROLL POWER BENDING ROLL, S/N 57222

GROTNES C-5700-A3-ROLL UNIVERSAL BENDING MACHINE, S/N 0356

POWER SQUARING SHEAR

PIRANHA M1/4-10 POWER SQUARING SHEAR, S/N 1109, ¼” X 10’ CAPACITY, 6’ SQUARING ARM, PROGRAMMABLE CONTROL

ROBOTIC WELDING CELLS

2016 PRE-TEC/FANUC ROBOT M-20IA 6-AXIS ROBOTIC WELDING CELL, S/N A05B-1225-B702, W/ FANUC SYSTEM R-30IB ROBOT CONTROLLER, S/N E16832412, W/ PENDENT CONTROL, PRETEC PLASMA ARC WELDING SYSTEM, FRONIUS TRANSTIG 4000 POWER SOURCE W/ PLASMA MODULE 10, W/ HIGH POINT OSA-LATOR T-1000-2X-HT S/N T-HT-12-16-HP-022, 2 STATION, 1400 LB PAYLOAD TOTAL, 3.2 SEC INDEXING TIME

2004 DAIHEN AX-MV6 6-AXIS ROBOTIC WELDING CELL, S/N 1L7700YZ5435708, W/ DAIHEN AX-CMN1-J000 ROBOT CONTROLLER, S/N L8800YZ5435602, W/ PENDENT CONTROL, DAIHEN AXPT1001-EC ROBOT WELD POSITIONER, S/N L7776YK5266102, K-TIG WELDING CONTROL, S/N CON-001 016, K-TIG 1000 DIGITAL INVERTER SMAW/TIG ARC WELDING POWER SOURCE, S/N J1607592003, DAIHEN ALMEGA 300P DIGITAL ELECON INVERTER

2004 DAIHEN AX—MV6 6-AXIS ROBOTIC WELDING CELL,S/N 1L7700YZ5436518, W/ DAIHEN AXCMN1-J000 ROBOT CONTROLLER, S/N L8800YZ5436213, W/ PENDENT CONTROL, DAIHEN AXPT1001-EC ROBOT WELD POSITIONER, S/N L7776YK5266101, LINCOLN PRECISION 375 PRECISION TIG POWER SOURCE, S/N U1100600297, THERMAL ARC HE150 COOLANT RECIRCULATOR SYSTEM, THERMAL ARC WC100B PLASMA WELDING CONSOLE, DAIHEN ALMEGA 300P DIGITAL ELECON INVERTER

SPOT WELDING

170 KVA JANDA PMFD317036 SPOT WELDER, S/N P3182, W/ MEDAR DEP100S WELD CONTROL

100 KVA PEER P-100 SPOT WELDER, S/N 14908, W/ TECHTRONIC T2050 WELD CONTROL

75 KVA TELEDYNE PEER P-100 SPOT WELDER, S/N 900076, W/ ENTRON WS500 WELD CONTROL

50 KVA BANNER 1AP50A12 SPOT WELDER, S/N 4128, W/ TECHNITRON T2050 WELD CONTROL

GANTRY, SEAM, & CIRCULAR WELDING SYSTEMS

MILLER 9’ GANTRY WELDER SYSTEM COMPRISING JETLINE ALC-101-6 WELD HEAD, MILLE MILLERMATIC WELD OSCILLATOR, JETLINE ALC-101 ARC LENGTH CONTROL, MILLER TRAVEL MASTER SB-10D SIDE BEAM CONTROL, JETLINE 9029 WIRE FEED CONTROL, W/ RANSOME 5P-B WELDING POSITIONER, S/N 1329276,30″ DIA TABLE, 500 LB TABLE CAPACITY

JETLINE ENGINEERING CW5-72Z CIRCULAR WELDER, S/N 940439, W/ JETLINE ALC-101-6 WELD HEAD, MILLER MAXSTAR 300DX POWER SOURCE, S/N KK286808, BERNARD 3500SS CHILLER, S/N WC27002, JETLINE ALC-101 ARC LENGTH CONTROL, SERIES 9600 CONTROL AND 9026 CARRIAGE CONTROL

ITW WELDING AUTOMATION CIRCULAR WELDER SYSTEM COMPRISING MILLER TRAVEL MASTER GMAW GANTRY, KOIKE ARONSON HD25A/T WELD POSITIONER, S/N 951785,, JETLINE ALC-401-6 WELD HEAD, S/N 080387, JETLINE ALC-101 ARC LENGTH CONTROL W/ 9029 WIRE FEED CONTROL, MILLER TRAVEL MASTER SB-10D SIDE BEAM CONTROL, MILLER MAXSTAR 300DX, S/N KK303583, MILLER CHILLER, AND MILLER TIB RUNNER CART

JETLINE ENGINEERING 24″ SEAM WELDER, K-TIG 1000 DIGITAL INVERTER SMAW/TIG ARC WELD POWER SOURCE, S/N J16125920001K-TIG THERMACOOL 1000 CHILLER, DUAL JETLINE 9600 SERIES WIRE FEED CONTROLS, JETLINE DAM-2-MLR-1 WELD CURRENT CONTROL

JETLINE ENGINEERING 8’ SEAM WELDER, S/N NA, W/ JETLINE ARC LENGTH CONTROL, 9029 WIRE FEED CONTROL, 9026 CARRIAGE CONTROL

AIRLINE/ PERFECTO 48″ SEAM WELDER, S/N 0569, W/ MILLER SYNCROWAVE 350 LX SQUARE WAVE POWER SOURCE, S/N LB010165 W/ VERSA-TIG CHILLER, JETLINE WELD HEAD, JETLINE ALC-201 ARC LENGTH CONTROL, DUAL 9600 SERIES CONTROLS W/ MAG-8000 MAGNETIC ARC CONTROL

WELDING POSITIONERS

KOIKE ARONSON MD5000 WELDING POSITIONER, S/N 936, 54″ X 54″ TABLE, 11,000 LB CAPACITY

ARONSON HD25 WELDING POSITIONER, S/N 54-248, 30″ X 30″ TABLE, 2500 LB CAPACITY

PRESTON-EASTIN PA30HD-6 WELDING POSITIONER, S/N PA30HD-158, 36″ X 36″ TABLE, 3000 LB CAPACITY

2000 KOIKE ARONSON LD-300KAI TIG WELD POSITIONER, S/N 10408, 18″ DIA TABLE, 660 LB TABLE CAPACITY

(3) 2016 KOIKE SANSO LD-300R WELD POSITIONERS, S/N A0427, A0428, & A0424, 18″ DIA TABLE, 300 KG TABLE CAPACITY

(4) 2012 KOIKE SANSO LD-300R WELD POSITIONERS, S/N 0210, 0214, 0263 & 0218, 18″ DIA TABLE, 300 KG TABLE CAPACITY

KOIKE ARONSON LD300N-TIG-1 WELD POSITIONER, S/N 9Z01, 14″ DIA TABLE, 660 LB CAPACITY

FUME COLLECTION SYSTEMS

(8) MICROAIR MX3510 COLLECTION SYSTEMS

(4) AIR FLOW SYSTEM VIBRA-PULSE COLLECTION SYSTEMS

(2) MICROAIR TASKMASTER TM 1000 COLLECTION SYSTEMS

WELDERS

(14) MILLER MAXSTAR 300 DX POWER SOURCES W/ MILLER CHILLER ON MILLER TIG RUNNER WELD CART

(11) MILLER SYNCROWAVE 350LX SQUARE WAVE POWER SOURCES

(4) MILLER SYNCROWAVE 250 POWER SOURCE W/ BERNARD 3500SS CHILLERS

LINCOLN 375 PRECISION TIG WELDER, S/N U11011006229

LINCOLN POWERWAVE 355M POWER SOURCE, S/N U1040805062, W/ LINCOLN POWER FEED 10M, S/N U1031020260

HOBART ULTRAFLEX 350 POWER SOURCE, S/N 296WS09366, W/ COBRA PUSH-PULL GMAW WIRE FEEDER, S/N 35121

MILLER DYNASTY 300DX POWER SOURCE, S/N KK272872, VERA-TIG VTSL3400 MULTI TORCH SELECTOR AND MILLER CHILLER ON MILLER TIG RUNNER WELD CART

MILLER DYNASTY 300DX POWER SOURCE, S/N LF305744 W/ MILLER CHILLER ON MILLER TIG RUNNER WELD CART

PLANISHERS

AIRLINE 72″ PLANISHER, S/N 0569, RADIOTROL SPEED CONTROL

PECK 60″ PLANISHER, S/N 8574

PANDJIRIS PLANISHER, S/N 12941E00

HYDRAULIC EXPANDERS

(2) PERFECTO EXPANDERS, S/N NA, 24″ TABLE DIA, W/ ENERPAC PER8418C HYDRAULIC PUMP, S/N C1395C, 10,000 PSI, 12.5 HP

ACROLINE EXPANDER, S/N NA, 16″ X 16″ TABLE, W/ VICKERS 10 HP HYDRAULIC UNIT

GROTNES HYDRAULIC EXPANDER, 36″ DIA TABLE, S/N NA, W/ 10 HP HYDRAULIC UNIT

HYDRAULIC EXPANDER, 42″ DIA TABLE, 10 HP LINCOLN HYDRAULIC UNIT

RING EXPANSION LINE COMPRISING (5) RIPPLERS W/ MCLEAN HEAT EXCHANGERS, EATON VICKERS PUMPS

TOOL ROOM

AMERICAN STYLE C 16″ X 54″ LATHE, S/N 78610, 10″ 3-JAW CHUCK, BLOCK STYLE TOOL POST, 23-1500 RPM, NEWALL DP700 DRO

AMERICAN PACEMAKER 20″ X 48″ LATHE, S/N 64991-42, 18″ 3-JAW CHUCK, BLOCK STYLE TOOL POST, 13-800 RPM

HARRISON M400 LATHE, 12″ 3-JAW CHUCK, 16″ SWING X 36″ BETWEEN CENTERS, 40-2000 RPM, BLOCK STYLE TOOL POST

VICTOR 1640 LATHE, S/N 561080, 16″ SWING X 40″ BETWEEN CENTERS, 65-1800 RPM

2013 BIRMINGHAM YCL-1640 LATHE, S/N 340038, 9.5″ 3-JAW CHUCK 16″ SWING X 40″ BETWEEN CENTERS, 35-2000 RPM, UNIQ SDS6-2V DRO

DOALL ZV-3620 VERTICAL BANDSAW, S/N 265-79217, 30″ X 36″ TABLE, 35″ THROAT

ROLL-IN ALL-PURPOSE VERTICAL BANDSAW, 18″ X 30.5″ TABLE, 15″ THROAT

TREE 2UVR VERTICAL MILLING MACHINE, S/N 0394, 10.5″ X 42″ TABLE, 60-3300 RPM SPINDLE SPEED, 1.5 HP

SPRINGFIELD TOOL & DIE PUNCH PRESS

NIAGARA NO. 180 BEADER CRIMPER, S/N 72427

ALSO AVAILABLE; (5) DIAMOND GROUND PRODUCTS PIRANHA III TUNGSTEN GRINDERS, DISC SANDERS, AND MORE

COORDINATE MEASURING MACHINES

LK G-90C COORDINATE MEASURING MACHINE, S/N NA, 119″ X 62″ TABLE, RENISHAW PH10M PROBE, RENISHAW PI200 PROBE INTERFACE, RENISHAW PHC-10-20 PROBE HEAD CONTROLLER

MITUTOYO CHN1612 COORDINATE MEASURING MACHINE, S/N 9010003, MITUTOYO CMMC-36 CONTROL, RENISHAW P14 PROBE INTERFACE W/ PHC 10 PROBE HEAD CONTROLLER

2018 FAROARM QUANTUM S 8-AXIS PORTABLE METROLOGY ARM

X-RAY SYSTEMS AND INSPECTION

COMET XRS-160 X-RAY SYSTEM, S/N 627493, COMET XRG CONTROL, 9’ X 10’ X 10’ BOOTH, W/ WILLICK ENGINEERING EE-LFR30-C X-RAY HEAD

BOSELLO X-RAY SYSTEM COMPRISING PHILIPS MCN 168 X-RAY GENERATOR, S/N 908669, W/ MGC30 READ OUT

2017 GE INSPECTION TECHNOLOGIES STRUCTURIX M ECO X-RAY PROCESSOR, S/N 1703

FLUORESCENT PENETRANT INSPECTION LINE W/ WASH TANK,DRY OFF OVEN, FLUORESCENT APPLICATOR BOOTH AND LAMP INSPECTION BOOTH, 30″ W X 36″ T CAPACITY

MISC

(2) EMR ACRALINE DRUM PUNCH MACHINES, S/N NA, GE FANUC SERIES 18-M CNC CONTROL AND FAGOR CONTROL

KEMAC INDUSTRIAL HEATED WASH SYSTEM, S/N 0493, 3’ DIA TABLE X 5’ T CAPACITY, 10 HP, W/ RUUD COMMERCIAL STORAGE TANK/ BOOSTER WATER HEATER

48″ UNKNOWN MAKE VIBRATORY FINISHER, S/N NA

28″ SWECO VIBRATORY FINISHER, S/N NA

(2) FILTER 1 BENCHTRON BFS32-3 DOWN DRAFT TABLES, S/N 02-36-30 & 02-26-331, 3 HP, 1200 CFM

DUAL DRAW WI16/8/8 WALK-IN AIR STATION, 16’L X 8’W X 8’T, (9) 2 HP BLOWER UNITS, SOUND DAMPENING WALL CURTAIN

TERMS:

• Sale Conducted in U.S. Funds (USD$)

• No Cash Accepted on Site

• Special Import / Export Guidelines: TBA – Will be provided in a downloable document

BUYER’S PREMIUM:

18% FOR ALL ONLINE PURCHASES

RIGGING CONTACTS:

Sermaq

Eleuterio Juarez V.

Phone 1: +52 (462)210-0343

Phone 2: +52 (664)501-0199

ventastj2@sermaq.com.mx

Campillo Gruas y Maniobras

Humberto Espinoza

Cell: +52 (664)628-7402

Office: +52 (664)626-1226

humberto.espinoza@campillo.com.mx

Barbara Campillo

Phone: +52 (664)626-1226

barbara@campillo.com.mx

TRUCKING CONTACTS:

Grupo Turbo Express

Phone: (619)661-6544

Fax: (619)661-9035

michelle.chavarria@turboexpress22.com

http://www.turboexpress22.com

Express Service Transport Inc

Israel Delgado

Phone: (619)348-7024

Grupo JD

Fernanda Garcia

Phone: +52 (664)623-2330