PUBLIC ONLINE AUCTION | AUCTION CLOSES: WEDNESDAY, JANUARY 25 STARTING AT 10:00 AM PST

WEDNESDAY, JANUARY 25 | 10:00 AM PST

PUBLIC ONLINE AUCTION

FULL FACILITY CLOSURE

AVCORP AEROSPACE COMPOSITE FABRICATION

ONLINE AUCTION CLOSES: WEDNESDAY, JANUARY 25 STARTING AT 10:00 AM PST

2-DAY INSPECTION: MONDAY, JANUARY 23 AND TUESDAY, JANUARY 24 FROM 9:00 AM TO 3:00 PM PST

LOCATION: 1551 WEST 139TH STREET, GARDENA, CA 90249

2012 PARPAS XS-75 CNC 5-AXIS GANTRY MILL, 2008 CINCINNATI VIPER 6000 FIBER PLACEMENT SYSTEM, BERTSCHE P5 5-AXIS VERTICAL MACHINING CENTERS, (8) TEC & ASC AUTOCLAVES FROM 2014, 2013 CINCINNATI CNC TAPE LAYER, LAB, OVERHEAD CRANES TO 30 TON CAPACITY, FREEZERS, GENERATORS, AIR COMPRESSORS, SCISSOR LIFTS, ELECTRIC CARTS, CABINETS, RACKING AND RELATED ITEMS

FIBER PLACEMENT

2008 CINCINNATI MODEL M46 VIPER FPS-6000 CARBON FIBER PLACEMENT SYSTEM, S/N TB01C01070002, (7) MACHINE AXES AND (2) PROCESS AXES, X-AXIS: 38’, Y-AXIS: 60 DEGREES BY 15.9’, Z-AXIS: 13”, MODEL CM100 CNC CONTROL, CARRIAGE CREEL CABINET WITH (32) SPOOLS, OPERATOR CONTROL PANEL W/ TOUCHSCREEN CONTROL, (2) HEADSTOCKS AND (2) TAILSTOCKS, CARRIAGE FIBER PLACEMENT HEAD DISPENSES UP TO (32) TOWS (.125” AND .250” WIDE MATERIAL), CUTS, CLAMPS, AND RESTARTS, VIDEO CAMERA, RENISHAW PART PROBE, (BUILDING #3)

HIGH SPEED GANTRY MILL

2012 PARPAS MODEL XS-75 HIGH SPEED CNC 5 AXIS, ASSET #A0174, X-AXIS: 275.6”’, Y-AXIS: 196.85”, Z-AXIS: 78. 74”, A: +/-110 DEGREES, C: CONTINUOUS, 3,148 IPM X AXIS, 1,574 IPM Y AXIS, 224” BETWEEN COLUMNS, PALLET SIZE 196” X 165”, TWETT 5-AXIS MILLING HEAD W/ AUTOMATIC CARTRIDGE CHANGER, 24,000 RPM SPINDLE, 80 HP, HSK-63-A TAPER, 48-POSITION ATC, SIEMENS 840D CNC CONTROLS, THRU SPINDLE COOLANT, ENCLOSURE W/ RETRACTABLE COVER, “TTCS” TOTAL THERMAL CONTROL SYSTEM, BLUM LASER TOOL PRESETTER, PROBE, (CRATED, NEVER BEEN USED), (BUILDING #25)

NON-DESTRUCTIVE TESTING

2016 ARCADIA MULTI-AXIS HIGH SPEED SQUIRTER – GANTRY STYLE ULTRASONIC INSPECTION SYSTEM, DATA REVIEW STATIONS, S/N AA1-UTG-1002, ASSET #A0227, (BUILDING #5)

2010 MISTRAS GROUP MODEL UPK-288G, NON-DESTRUCTIVE C-SCANNING GANTRY ULTRASONIC INSPECTION 12-AXIS GANTRY, ASSET #A0147 501048, ULTRASONIC THROUGH TRANSMISSION AND PULSE ECHO SCANNING, APPROX. 24’L X 16’W X 16’H, PRECISION MECHANICAL CONTROL, WITH AEROTECH MOTION CONTROLLERS, REMOTE C-SCAN GANTRY PENDANT CONTROL, TRENDNET TEG-616G GIGABYTE SWITCH, (6) HEAVY DUTY STEEL COLUMNS SUPPORTING GRANITE RAILS, TWIN OVERHEAD TRAVELING INSPECTION HEADS, WATER RECLAMATION PIT, WITH RECIRCULATING PUMP, (2) FILTERS, COMPUTER CONTROLS, (BUILDING #5)

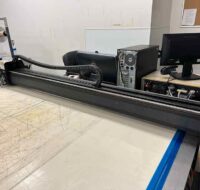

AUTO TAPE LAYER

2013 CINCINNATI MODEL SFTL (SMALL FLAT TAPE LAYER) AUTOMATIC FLATBED TAPE LAYING MACHINE, S/N TA00G01110001, ASSET #501078 A0006, (ATL #3), CINCINNATI MAG “CHARGER”, APPROX. TRAVEL: X-AXIS: 240”, Y-AXIS: 127”, Z-AXIS: 5.9”, C-AXIS: 180 DEGREE ROTATION, 127”W X 30’L VACUUM TABLE, 12”W ROLL CAPACITY, LASER CUTTER TRIMMER, MODEL MAG CM100 CNC CONTROL, HOPE INDUSTRIAL SYSTEMS TOUCH PAD PANEL CONTROL, VACUUM PUMP, (2) WELDEX VISION I CAMERAS, SLICK MODEL M4000 SAFETY LIGHT CURTAINS, (BUILDING #4)

VERTICAL MACHINING CENTERS

2013 BERTSCHE P5, MODEL MODEL P5-00804-000-00, 5-AXIS FLOOR BEAM TRIM AND DRILL MACHINE, S/N 7655, ASSET #A1070, WITH TWIN TABLES, TWIN SPINDLES, EACH SIDE WITH 270” X 60” X 30” CAPACITY, SINGLE SPINDLE, WORK ENVELOPE: X1 AND X2 AXES = 272”, Y1 & Y2 AXES = 57” AND 67”, Z1 AND Z2 AXES = 31.5”, A = +/- 92.5 DEGREES, C = +/-200 DEGREES, 20,000 RPM SPINDLE SPEED, WITH 30-POSITION AUTOMATIC TOOL CHANGER, SERVO DRIVES, PART PROBING SYSTEM, SIEMENS MODEL 840D CNC CONTROLS, SHARED COOLANT, AIR AND FLUID FILTRATION SYSTEMS, (BUILDING #69)

2009 BERTSCHE P5, MODEL P5-00792-000-00, 5-AXIS FLOOR BEAM TRIM AND DRILL

MACHINE, S/N 7392, ASSET #A1080, BERTSCHE #1, 240” X 60” X 30” CAPACITY, SINGLE SPINDLE, WORK ENVELOPE: X AXIS 270”, Y AXIS 68”, Z AXIS 60”, A = +/- 92.5 DEGREES, C = +/-185 DEGREES, 20,000 RPM SPINDLE, AUTOMATIC TOOL CHANGER, PART PROBING SYSTEM, SIEMENS MODEL 840D CNC CONTROL, COOLANT, AIR AND FLUID FILTRATION SYSTEMS, (2020 REBUILD), (BUILDING #69)

HOT DRAPE FORMERS

2015 ASC PROCESS SYSTEMS MODEL HDF-44X274-200F-12T, 30”W X 20’L,

S/N 14495, ASSET #A0059, (HDF #5), CARBON COMPOSITE, 200°F TEMPERATURE, WITH AIRTECH MODEL L-100 5 HP VACUUM PUMP, (BUILDING #1)

2012 ASC PROCESS SYSTEMS, 30’W X 20’L HOT DRAPE FORMER, S/N 12156, HDF#3A AND 3B, ASSET #A0009, (HDF #3A AND #3B), (6) ZONES WITH 10 IR HEATING LAMPS/ZONE, WITH HONEYWELL MODEL UDC120L TEMPERATURE HIGH LIMIT SET POINT CONTROL, TWIN CHAMBERS, AIRTECH TYPE L-100 VACUUM PUMP SYSTEM, 70 CFM, 0.5 TORR, 2.7 LITER VACUUM, 5 HP, HEATER BOX AND VACUUM FRAME, 248”L X 29’W, ALUMINUM FRAME WITH SILICON DIAPHRAGM, STRUCTURAL STEEL TUBULAR FRAME, ALLEN-BRADLEY MODEL COMPACT LOGIX PLC CONTROL, AND DELL MODEL OPTIPLEX 780 COMPUTER

2012 ASC PROCESS SYSTEMS, 30’W X 20’L HOT DRAPE FORMER, S/N 12218, ASSET #A0010, (HDF #4), MFR #3, (6) ZONES WITH 10 IR HEATING LAMPS/ZONE, WITH HONEYWELL MODEL UDC1 CONTROL, VACUUM PUMP SYSTEM, 5 HP, HEATER BOX AND VACUUM FRAME, 248”L X 29’W, ALUMINUM FRAME WITH SILICON DIAPHRAGM, STRUCTURAL STEEL TUBULAR FRAME, ALLEN-BRADLEY MODEL COMPACT LOGIX PLC CONTROL, AND DELL MODEL OPTIPLEX 780 COMPUTER

2011 LAMINATING TECHNOLOGY BED SIZE 1 04’W X 338”L TWIN BED HDF, S/N L T/6129/2011, ASSET #A0025, (HDF #2), BED SIZE 104’W X 338”L, OPERATING TEMPERATURE 260 TO 350°F, WITH YOKOGAWA MODEL PD TEMPERATURE SET POINT CONTROLS, HEATER BANK WITH IR BULBS, SILICON MEMBRANE, PNEUMATIC CYLINDERS FOR RAISING AND LOWERING FORMING HOOD, TWIN BEDS, WITH SHARED 30’L TROLLEY SYSTEM, BECKER VACUUM PUMP TYPE U4.1 00SA/K, S/N H2656739, (2012), APPROX. 5 HP MOTOR, YOKOGAWA MODEL CX2000 TOUCH PAD CONTROL, AND PROGRAMMABLE TEMPERATURE AND PRESSURE CONTROLS

AUTOCLAVES

2014–2012 ASC PROCESS SYSTEMS MODEL EC3X25-150P475F-6S6P16T, 3’ DIA. X 25’L HORIZONTAL ELECTRIC AUTOCLAVES, S/N 13484, (AUTOCLAVE #24), S/N 11323 (AUTOCLAVE #22), S/N 11324 (AUTOCLAVE #23), ECONOCLAVE, RATED 150 PSI @ 475°F, ASME DESIGN PRESSURE 165 PSI @ 450°F, 0.375” SHELL THICKNESS, 0.2186” MINIMUM HEAD THICKNESS, WITH HONEYWELL MODEL UDC120L TEMPERATURE HIGH LIMIT SET POINT CONTROL, HYDRAULIC SWING-UP COVER, HYDRAULIC LOCKING DEVICE, FRONT END LOADER CART SERVICING ALL (5) AUTOCLAVES, APPROX. 18’W X 25’L, RAIL GUIDED TRAVEL, AND ELECTRIC MOTOR DRIVES FOR TRAVEL AND LOADING, FRACTIONAL HP MOTORS

2009 THERMAL EQUIPMENT 20’D X 50’L HORIZONTAL AUTOCLAVE, ASSET #A0085, (AUTOCLAVE #18), 150 PSI, 475°F, TRACK MOUNTED TRANSFER CART, COMPUTER CONTROLS, (96) TYPE J THERMOCOUPLE JACKS, (48) VACUUM LINES WITH TRANSDUCERS, GAS FIRED BURNER, NORTH AMERICAN SERIES 4796-20/X7467, MODEL 2936U-8300 100 HP EXHAUST BLOWER, S/N 2142640, HYDRAULIC DOOR LOCK/UNLOCK, ALLEN-BRADLEY MODEL PANELVIEW PLUS 1000 TOUCH SCREEN CONTROL PANEL, (5) HONEYWELL CHART RECORDERS, AND DELL COMPUTER CABINET, AUTOCLAVE #18, (BUILDING #3 BEHIND EAST SIDE OF BUILDING)

2011 TARICCO HORIZONTAL AUTOCLAVE, S/N 1101, ASSET #A1031, (AUTOCLAVE #19), ELECTRIC, 150 PSI, 475°F, 10’D X 35’L CHAMBER, TRACK MOUNTED PARTS TRANSFER CAR, ALLEN-BRADLEY MOTOR CONTROL CENTER, COMPUTER CONTROLS, (48) TYPE J THERMOCOUPLE JACKS, (48) VACUUM LINES WITH TRANSDUCERS, AND AMCOT COOLING TOWER, (ASSET #501029 AND #501061), (BUILDING #32)

1987 HORIZONTAL AUTOCLAVE, S/N 478, ASSET #A1051, (AUTOCLAVE #13), ELECTRIC, 270 PSI OPERATING PRESSURE, 650°F OPERATING TEMPERATURE, 14’6”D X 39’5”L CHAMBER, WITH TRACK MOUNTED PARTS TRANSFER CAR, CONTROLS COMPLETED BY THERMAL ENGINEERING CORPORATION, WITH ALLEN-BRADLEY MOTOR CONTROL CENTER, OLDER COMPUTERIZED CONTROLS, (3) KINNEY MODEL 7.5 HP VACUUM PUMPS, (36) TYPE J THERMOCOUPLE JACKS, (36) VACUUM LINES, WITH TRANSDUCERS, AND RECOLD MODEL PS-200 COOLING TOWER, S/N 01940

MATTHEWS HORIZONTAL AUTOCLAVE, S/N 5184, ASSET #A1027, (AUTOCLAVE #1), ELECTRIC, 135 PSI, 350°F, 70”D X 141”L CHAMBER, WITH COMPUTER CONTROLS, (12) TYPE J THERMOCOUPLES, (8) VACUUM LINES WITH TRANSDUCERS, HONEYWELL CHART RECORDER, ALLEN-BRADLEY MODEL PANELVIEW 700 PLUS, (BUILDING #32)

THERMAL EQUIPMENT HORIZONTAL AUTOCLAVE, S/N 292, ASSET #A1030, (AUTOCLAVE #3), ELECTRIC, 315 PSI, 650°F, 47”D X 112”L CHAMBER, VACUUM PUMP, COMPUTER CONTROLS, (12) TYPE J THERMOCOUPLE JACKS, (6) VACUUM LINES, WITH (3) TRANSDUCERS, HONEYWELL CHART RECORDER, ALLEN-BRADLEY MODEL PANELVIEW 700 PLUS CONTROL, (BUILDING #32)

OVERHEAD BRIDGE CRANES

ACTION CRANE 30-TON X 60’ SPAN TOP RUNNING DOUBLE GIRDER BRIDGE CRANE,

S/N 3316928, ASSET #A 1072, APPROX. 100’ CRANEWAY, WITH (2) 15-TON CABLE HOISTS, (BUILDING #69)

DEMAG 20-TON X 50’ SPAN TOP RUNNING DOUBLE GIRDER BRIDGE CRANE, OUT-DOOR, APPROX. 50’ CRANEWAY, WITH (5) A-FRAME SUPPORTS AND (5) SINGLE 8” RECTANGULAR STEEL COLUMN SUPPORTS, AND DEMAG 20-TON RADIO WIRE ROPE HOIST, S/N L10042, (BUILDING #3 BEHIND EAST SIDE OF BUILDING)

(3) ACE CRANE SERVICE 15-TON X APPROX. 50’ SPAN TOP RUNNING DOUBLE GIRDER BRIDGE CRANES, S/N S-10303B, S/N UNKNOWN, AND S/N S-10309A, APPROX. 200’ CRANEWAY, SUPPORTED BY BUILDING COLUMNS, EACH WITH DETROIT HOIST AND CRANE COMPANY PENDANT CONTROLLED ELECTRIC WIRE HOIST, (BUILDING #73)

ANDERSON CRANE 15-TON X 60’ SPAN TOP RUNNING DOUBLE GIRDER BRIDGE CRANE, ASSET #A1066, APPROX. 80’ CRANEWAY, WITH CABLE HOIST, (BUILDING #10-OUTSIDE)

ANDERSON CRANE 15-TON X 60’ SPAN TOP RUNNING DOUBLE GIRDER BRIDGE CRANE, ASSET #A1066, APPROX. 80’ CRANEWAY, WITH CABLE HOIST, (BUILDING #10-OUTSIDE)

(2) CRANEVEYOR APPROX. 75’ SPAN X 240’ CRANEWAY TOP RUNNING DOUBLE GIRDER BRIDGE CRANES, S/N 408202-A AND S/N 408202-B, EACH DETROIT 15-TON ELECTRIC WIRE HOIST, MAGNETEK RADIO CONTROL, (1) WITH 5-TON AUXILIARY HOIST, (BUILDING #3)

DEMAG 10-TON X APPROX. 20’ SPAN OVERHEAD TRAVELING BRIDGE CRANE, S/N 10048, ASSET #5-1, MOUNTED WITH DEMAG RADIO CONTROLLED ELECTRIC WIRE ROPE HOIST, (BUILDING #5)

(2) DEMAG 10-TON X APPROX. 70’ SPAN TOP RUNNING SINGLE GIRDER BRIDGE CRANES, S/N 10P257-01, ASSET #10146L, AND S/N 10P257-02, ASSET #10147L, 220’ CRANEWAY SUPPORTED BY BUILDING COLUMNS, MOUNTED WITH RADIO CONTROLLED DEMAG 10-TON ELECTRIC WIRE ROPE HOIST, (BUILDING #4)

P&H 10-TON X 60’ SPAN TOP RUNNING DOUBLE GIRDER BRIDGE CRANE, APPROX. 80’ CRANEWAY, WITH CABLE HOIST, (BUILDING #10-OUTSIDE)

NORTH AMERICAN 10-TON X 15’ SPAN FREESTANDING TOP RUNNING SINGLE GIRDER BRIDGE CRANE, S/N 40026, ASSET #A1026, WITH (4) 12”D X 20’H STEEL POST SUPPORTS, APPROX. 25’L CRANEWAY, AND BLACK BEAR 10-TON RADIO CONTROLLED ELECTRIC WIRE ROPE HOIST, (OUTSIDE OF AUTOCLAVE #19), (BUILDING #32)

NORTH AMERICAN 10-TON X 40’ TOP RUNNING SINGLE GIRDER BRIDGE CRANE, S/N 38525, WITH CABLE HOIST, (BUILDING #65)

NORTH AMERICAN 10-TON X 40’ SPAN FREE STANDING TOP RUNNING SINGLE GIRD-ER BRIDGE CRANE, ASSET #A0232, 12” DIAMETER STRUCTURAL STEEL PIPE SUPPORTS, 30’H, 60’ CRANEWAY, WITH BLACK BEAR WIRE ROPE HOIST, (BUILDING 10-OUTSIDE)

P&H 10-TON X 60’ SPAN TOP RUNNING DOUBLE GIRDER BRIDGE CRANE, APPROX. 80’ CRANEWAY, WITH CABLE HOIST, (BUILDING #10-OUTSIDE)

P&H 10-TON DOUBLE GIRDER BRIDGE CRANE, ASSET #A1067, (BUILDING #10-OUTSIDE)

(2) DEMAG 10-TON X APPROX. 70’ SPAN TOP RUNNING SINGLE GIRDER BRIDGE CRANES, S/N 10P257-01, ASSET #10146L, AND S/N 10P257-02, ASSET #10147L, 220’ CRANEWAY SUPPORTED BY BUILDING COLUMNS, MOUNTED WITH RADIO CONTROLLED DEMAG 10-TON ELECTRIC WIRE ROPE HOIST, (BUILDING #4)

PACIFIC CRANE & HOIST 2-TON X 25’ SPAN SINGLE GIRDER MONORAIL CRANE, S/N 15X552-02, (AIR-LOCK ROOM #2), WITH RADIO CONTROLLED DEMAG 1-TON ELECTRIC CHAIN HOIST, (2) 12” RECTANGULAR STEEL TUBULAR FRAME SUPPORT STRUCTURES, 12” I-BEAM MONORAIL, AND PACIFIC CRANE & HOIST 2,000 LB MAXIMUM LIFTING BEAM, S/N 14X539-LB3, 20’L, (BUILDING #4)

2,200 LB X 25’ SPAN FREE STANDING UNDERHUNG SINGLE GIRDER BRIDGE CRANE, ASSET #A0012, STEEL STRUCTURE, 25’ SPAN X 25’ CRANEWAY, WITH (4) COLUMNS BOLTED TO FLOOR, SINGLE BEAM UNDERHUNG, MOUNTED WITH DEMAG 2,200 LB CAPACITY ELECTRIC CHAIN HOIST, 2-WAY PENDANT CONTROL, AND CALDWELL 1-TON CAPACITY LIFTING BEAM, 18’L, (BUILDING #4)

PACIFIC CRANE & HOIST 2-TON X 15’ SPAN FREE STANDING UNDERHUNG SINGLE GIRDER BRIDGE CRANE, S/N 12P377, STEEL STRUCTURE, 15’ SPAN X 20’ CRANEWAY WITH (4) COLUMNS BOLTED TO FLOOR, SINGLE BEAM MOUNTED, WITH (2) DEMAG 1,000 LB ELECTRIC CHAIN HOISTS, (BUILDING #4)

PACIFIC CRANE & HOIST 2-TON X 25’ SPAN SINGLE GIRDER MONORAIL CRANE, S/N 15X552-02, (AIRLOCK ROOM #2), WITH RADIO CONTROLLED DEMAG 1-TON ELECTRIC CHAIN HOIST, (2) 12” RECTANGULAR STEEL TUBULAR FRAME SUPPORT STRUCTURES, 12” I-BEAM MONORAIL, AND PACIFIC CRANE & HOIST 2,000 LB MAXIMUM LIFTING BEAM, S/N 14X539-LB3, 20’L, (BUILDING #4)

2-TON X APPROX. 24’ SPAN UNDERHUNG SINGLE GIRDER BRIDGE CRANE, CRANEWAYS ARE BUILDING COLUMN SUPPORTED, 40’L, MOUNTED WITH RADIO CONTROLLED CM MODEL LODESTAR 2-TON ELECTRIC CHAIN HOIST, (BUILDING #7)

NORTH AMERICAN 2-TON X APPROX. 22’ SPAN UNDERHUNG SINGLE GIRDER BRIDGE CRANE, S/N 400 15, BUILDING COLUMN SUPPORTED CRANEWAY, APPROX. 50’L, WITH (1) 2-TON ELECTRIC CHAIN HOIST, (BUILDING #7)

(2) NORTH AMERICAN 2-TON X APPROX. 18’ SPAN UNDERHUNG SINGLE GIRDER BRIDGE CRANES, S/N 32452, AND S/N: UNKNOWN, APPROX. 100’ CRANEWAY SUPPORTED BY BUILDING COLUMNS, MOUNTED WITH BLACK BEAR MODEL YHTD200 2-TON ELECTRIC CHAIN HOIST, PENDANT CONTROLLED, (BUILDING #7)

2-TON X 16’ SPAN FREE STANDING UNDERHUNG SINGLE GIRDER BRIDGE CRANE, ASSET #A1025, MOUNTED WITH CM LODESTAR ELECTRIC CHAIN HOIST, PENDANT CONTROLLED, 6-WAY, 90’ CRANEWAY, AND (10) 8” I-BEAM SUPPORTS, (BUILDING #32)

LAB & INSPECTION

UNITED TESTING SYSTEMS MODEL SFM-20 TENSILE TESTER, S/N 1291553, ASSET #A1144, CALIBRATION #01-6104X, WITH BEMCO MODEL FTU3.2S-100/600 ENVIRONMENTAL CHAMBER, S/N 3432-1, (7/1982), APPROX. 350°F, LN2 COOLING, TRACK MOUNTED, (OPENING ON BOTTOM AND TOP), (1) VOSTRO 200 AND (1) MODEL OPTIPLEX 760 COMPUTER

MICRO-VU MODEL CENTURY 2014, 14” OPTICAL COMPARATOR, S/N 142, ASSET #A 1182, WITH MICRO-VU MODEL Q161 PROGRAMMABLE DIGITAL READOUT, W/ BASE CABINET

(3) BLUE M OVENS

FARO ARMS, MICROSCOPES, MITUTOYO & STARRETT INSPECTION TOOLS AND RELATED ITEMS

FREEZERS

2011 BALLY 660 SQ FT FREEZER, ASSET #A0056 501012, PANEL TYPE CONSTRUCTION, RATED @ -5 DEGREES F, (2) 15-TON CHILLERS, SINGLE ACCESS DOOR, WITH INTERTEX AUTOMATED STORAGE AND RETRIEVAL SYSTEM, LONG BED CAROUSEL TYPE, INTERTEX GROUP MODEL INT-TC7.1 TOUCH PAD CONTROL, SHUTTLE TYPE LOAD AND UNLOAD SYSTEM, (BUILDING 76)

1992 WALK-IN FREEZER, ASSET #A1138/501089, CONCRETE FOUNDATION, INSULATED METAL WALLS, APPROX. 30’ X 30’ X 10’H, 0°F, 900 SQ FT, WITH (2) RUSSELL 3-TON REFRIGERATION UNITS, (1992), AND (1) UNITY REFRIGERATION UNIT, (1998), (BUILDING 71)

MACHINE SHOP

SHARP MODEL TMV-DVS VERTICAL MILL, S/N 50401883

DOALL CONTOUR-MATIC 36” VERTICAL BAND SAW

W.F. WELLS MODEL F-16-1 HORIZONTAL BAND SAW, S/N A2479-F99420

ENCO 20” SQUARE COLUMN GEARED HEAD MILL DRILL

BLACKHAWK H-FRAME PRESS

WYSONG 36” FOOT SHEAR

SCISSOR & BOOMS LIFTS

GENIE MODEL Z-45/25 45’ BOOM LIFT, S/N Z-45-013128, ASSET #A1129 SL-005, HOURS UNKNOWN, 4-CYLINDER, 45’ BOOM

(2) 2011 JLG MODEL 3246ES, 700 LB ELECTRIC SCISSOR LIFTS, S/N 0200192540, (2009), ASSET #A0089 SL-004, AND S/N 0200199591, ASSET #A0088 SL-008, 31.75’ MAXIMUM TRAVEL HEIGHT

2009 JLG MODEL 1930ES, 500 LB ELECTRIC SCISSOR LIFT, S/N 0200192519, ASSET #A1118/SL-002, 18.8’ MAXIMUM TRAVEL HEIGHT

2011 JLG MODEL 1230ES, 500 LB ELECTRIC SCISSOR LIFT, S/N 0200199055, ASSET #A1131 SL009

TUGS & CARTS

TAYLOR-DUNN MODEL C0-426-48AC, 30,000 LB DRAWBAR PULL SIT DOWN RIDING ELECTRIC TUG, S/N 181745

(6) TAYLOR-DUNN ELECTRIC MAINTENANCE CARTS

2008 TAYLOR-DUNN MODEL E0-034-51, 12,000 LB DRAWBAR PULL STAND-UP RIDING ELECTRIC TUG, S/N 178265, ASSET #A1107

STANDBY GENERATORS

2016 GENERAC MODEL SG150KG189.0S18HPSYE, 150 KW, S/N 3000353106

2006 KOHLER MODEL 100RZG, LP FUEL, S/N 2126784

PLANT SUPPORT

MATERIAL HANDLING CARTS, RUBBERMAID CARTS, FILM PAYOFF REELS, LOCKERS, FLAMMABLE STORAGE CABINETS, MEDIUM DUTY CANTILEVER STORAGE RACKS,

STORAGE CABINETS, LIGHT DUTY STORAGE RACKS, METRO RACK AND RELATED ITEMS

TERMS:

NO DEBIT OR CREDIT CARDS! CASHIER’S CHECK, BUSINESS CHECK WITH BANK LETTER OF GUARANTEE, BANK WIRE TRANSFER. FULL PAYMENT MUST BE MADE NO LATER THAN 24 HOURS OF WINNING BID.

BUYER’S PREMIUM:

18% FOR ALL ONLINE PURCHASES.

REMOVAL:

ALL ITEMS MUST BE REMOVED NO LATER THAN WEDNESDAY, MARCH 8. PREPPING, LOADING & TRUCKING IS THE RESPONSIBILITY OF THE BUYER.